Service Center

Our Services

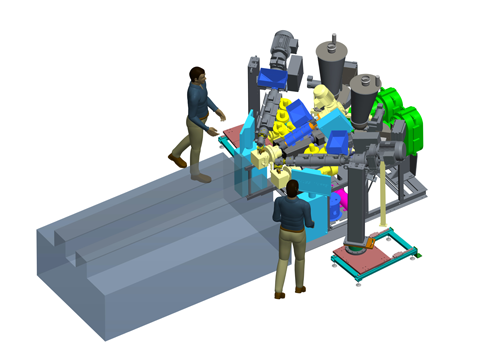

Engineering project

With a dedicated team of mechanical, electrical and software engineers and a cutting edge R&D and production facility, we can provide a total solution from initial design through manufacturing installation and plant operation.

Baekeland is constantly seeking new and improved process equipment, committed to meeting customer needs in the best way.

Process knowledge

Single screw extrusion process: One of the best process ideas is to improve the extrusion volume, thereby improving the production efficiency of single screw extruder. At the same time, the thermal homogeneity and material homogeneity have been greatly improved. This significant advantage is achieved through our optimized processing unit.

Counter-rorating twin-screw extrusion process: Optimized processing units provide a wide processing window, improve melt uniformity and reduce wear. It has been proven that this can be achieved by reducing the circumference velocity of the screw while ensuring better workability and achieving greater flexibility in profile/tube extrusion. The use of temperature-controlled screw and fan-cooled barrels also means minimal maintenance of the machining unit.

Pre-sale and after-sale services

Baekeland always provides excellent after-sales service to our customers, with an efficient and well-prepared technical team who can handle customer requests on the same day by providing original Baekeland spare parts. We also have a team of electrical technicians who can provide remote assistance from our factory. With Web service access, Baekeland technicians can connect remotely, diagnose and locate problems on the control system, verify possible misoperations on the system and install subtle repair software.